Food and Beverages

Food and Beverage Vessels

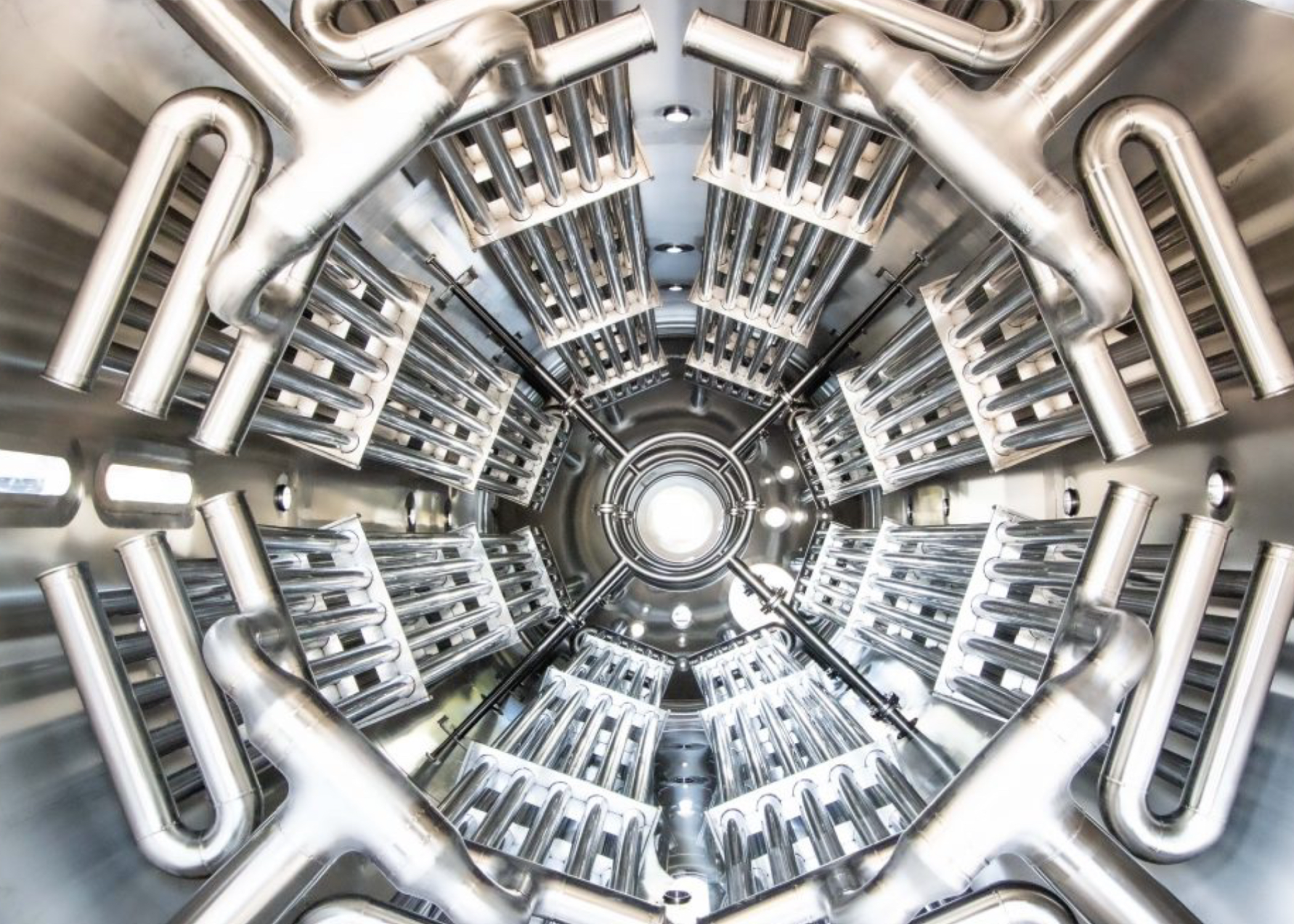

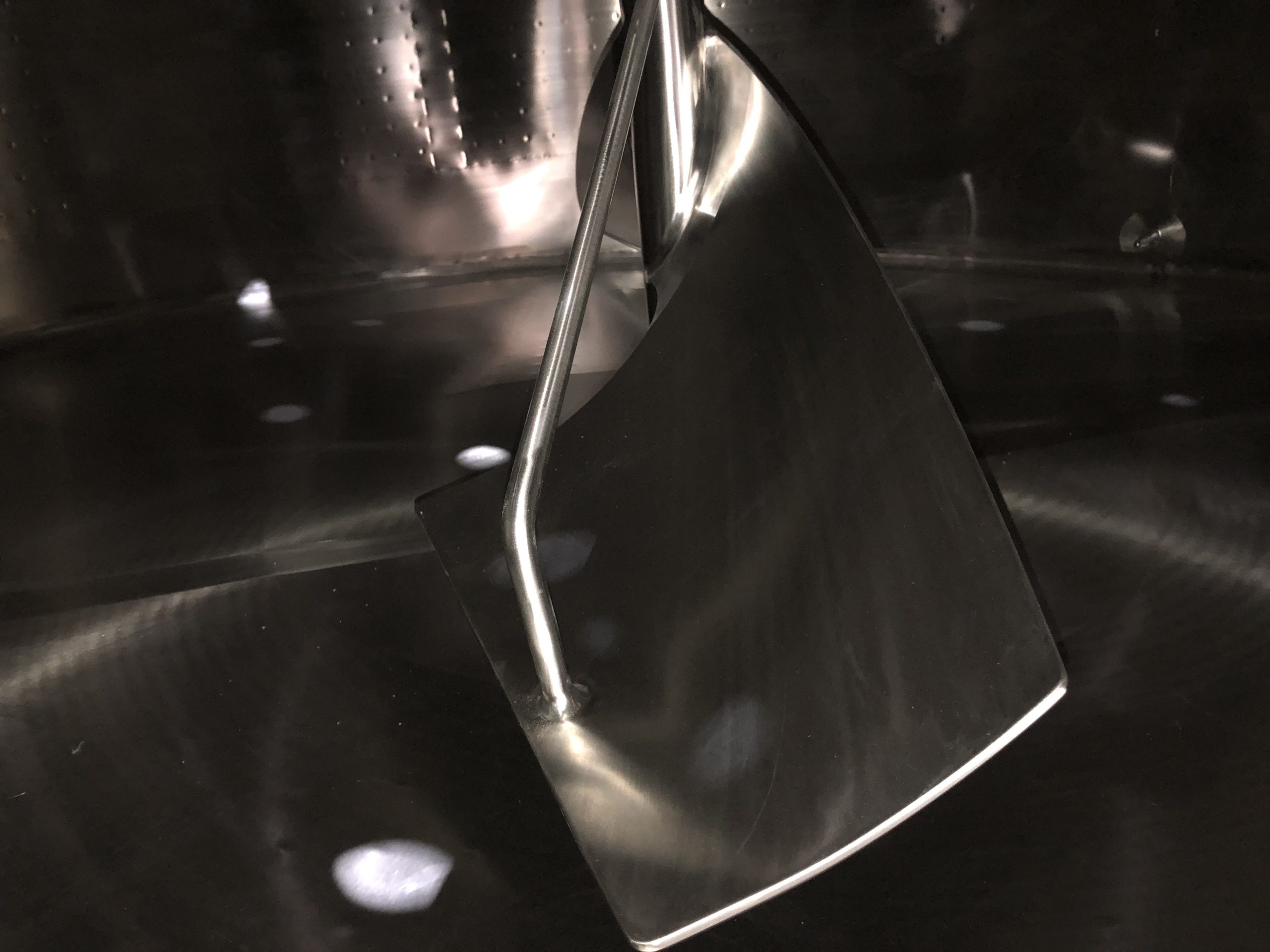

JBF Stainless manufactures a wide variety of mix tanks and storage tanks for the food, beverage, ozone and pure water industries. We manufacture our own agitators and are home to the self-cleaning Sanifoil Impeller and SaniBearing, a sanitary steady bearing designed to be easily disassembled and removed without tools. Our in-house Mixer Lab will define the fluid characteristics of your company’s product and develop the best solution for mixer performance.

- Mix Tanks

- Juice Tanks

- Kettles

- Sugar Tanks

- Blend Tanks

- Weigh Tanks

- Pellet Storage

- Portable Tanks

- Wine Tanks

- Pressure Vessels

- Balance Tanks

- Storage Tanks

Mix Tanks

- Horizontal Mix Tanks

- Large Storage Silos

- High Fructose Corn Syrup Tanks

- Concentrate Tanks

- Retrofit agitator kits

JBF manufactures it’s own economical heat transfer surface (HTS) for both low and high pressure heating and cooling applications.

Storage Tanks

Bulk Containers for storing, handling, and transferring liquids are an JBF’s specialty. These containers can be mounted on four-way forklift channels, pressure and/or vacuum rated, and can be stack-able.

Our 40,000 square foot manufacturing plant accommodates large tank fabrication. The tall building allows for one piece vertical assembly, which is a very economical manufacturing method. The actual building site or installation constraints may require on-site tank assembly. Seismic conditions are always considered.

Why Choose JBF?

Custom Manufacturing: Our in-house capabilities allow us to produce systems tailored to your exact specifications.

Innovative Technology: We are constantly evolving to incorporate the latest advancements in process engineering.

Whether you’re optimizing existing operations or embarking on a new project, JBF’s stainless steel systems provide the foundation for success. Let us partner with you to drive innovation and efficiency in your chemical processes.